We may ask ourselves why we need similar measurements and diagnostic methods. The answer is very simple. By continuously testing the bearings and rotating parts of the machines, unwanted stoppages and production losses can be avoided. In the vast majority of factories and plants, a sensor or bearing failure can cost production orders of magnitude more. Measurement assessment is determined according to ISO 10816-3 based on the measured results.

Therefore, I strongly recommend continuous assessment of equipment. How often should it be done? The question depends on how busy it is, how many operating hours it should be running. In the case of continuous operation, it is advisable to carry out a condition survey every month, so that the values measured over the months will show the beginning of deterioration as a trend.

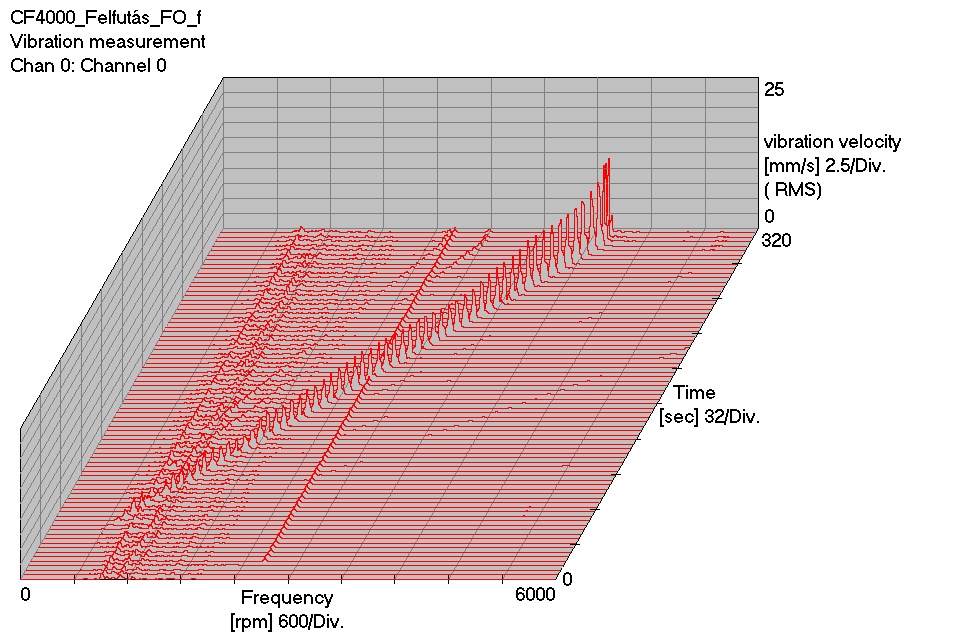

A start-up diagram for vibration analysis is investigated. You can see the vibration values of the components of different frequencies in the spectrum. The result is clearly visible, the vibration increases steadily as the rotation increases, this indicates an imbalance and is not due to resonant frequency.

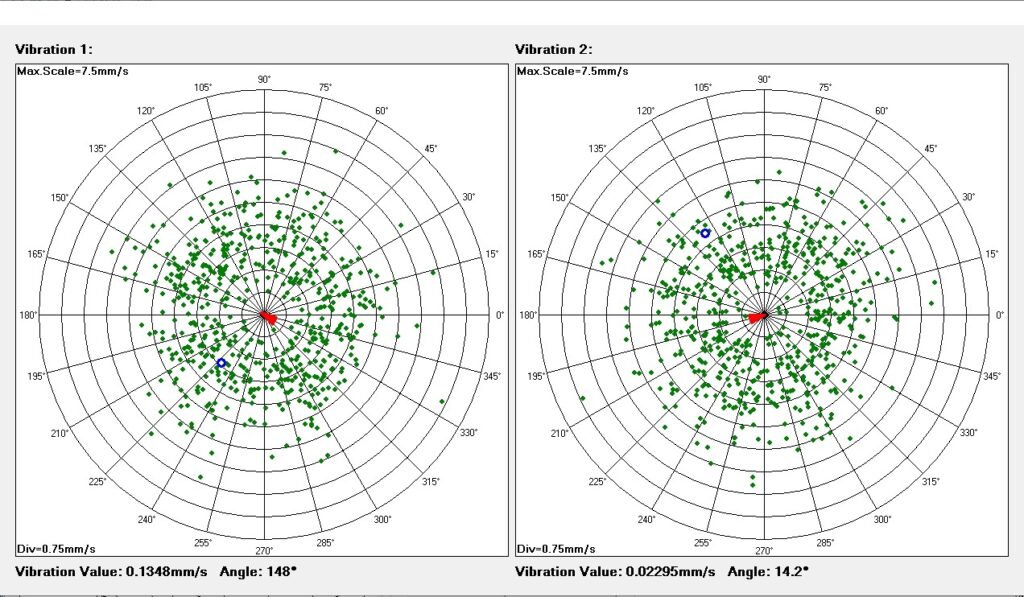

The result of balancing a centrifuge rotor:

The small red centre is actually a vector, indicating the angle at which the greatest degree of imbalance is. You can see that the red vector is tiny and the green dots show the resultant of the imbalance. Because the physical properties of the equipment (decanter) mean that the resulting imbalance is not always in the same place, the resulting vibration may appear to be circular, but this is perfectly correct.